Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

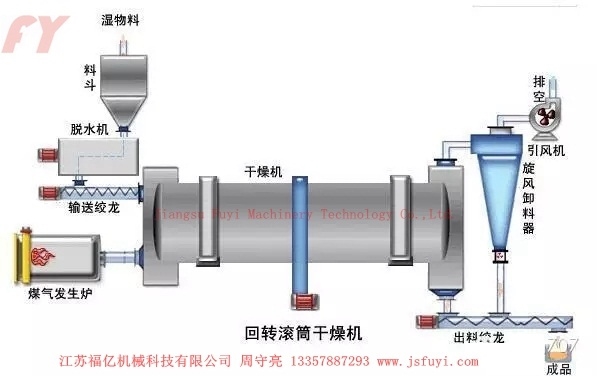

Working principle

Material from into the material box guide groove into the rotary cylinder, fall into the set inclined pushing copy board area, the material will along the copy board quickly slid into the cylinder of the deep, to reduce material and high temperature gas flow time and prevent pour material, material in entering a dry area of lifting plate, due to the body tilt and rotation, and entered the cylinder heat medium heat exchange, to dry the material, feed end in the cylinder, with shaking device, to prevent fertilizer in case of high temperature sintered on the inner wall, drying operation can be carried out as normal.

Drum dryer is a continuous dryer heated by heat conduction. It is suitable for drying liquid materials such as solution, suspension, colloid solution, etc..

Adaptive material

◎Chemical, mining, metallurgy and other industries large particles, drying, a large proportion of materials such as: mine, blast furnace slag, coal, metal powder, phosphate, ammonium sulfate.

◎For the drying of powder and granular materials with special requirements, such as HP foaming agent, lees, light calcium carbonate, activated clay, magnetic powder, graphite and slag.

◎Material requiring low temperature drying and requiring continuous drying in large quantities.

Performance characteristics

◎The drum dryer is highly mechanized and has large production capacity.

◎The fluid passes through the cylinder and has low resistance and low function consumption.

◎Good adaptability to material characteristics.

◎The operation is stable, the operation cost is low, and the drying uniformity of the product is good.

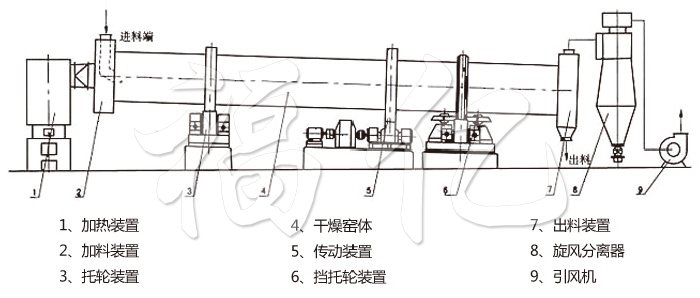

Schematic drawing

1. Heating device 2.Feeding device 3. supporting wheel device 4. Dry kiln 5.Driving device 6. Wheel supporting device 7.Discharging device

8.Cyclone separator 9. Fan

Technical specifications

|

Model |

Direct heating fair current |

Direct heating fair current |

Direct heating counter current |

Direct heating counter current |

Compound heating |

Compound heating |

|

Material type |

mineral |

HP blowing agent |

Blast furnace slag |

ammonium sulphate |

phosphate fertilizer |

coal |

|

Processing capacity (kg/h) |

1000 |

466 |

15000 |

20000 |

12000 |

5000 |

|

Output water content(%) |

30 |

13 |

6 |

1.5 |

5 |

6.5 |

|

Final water content(%) |

15 |

0.3 |

1 |

0.1 |

0.1 |

0.1 |

|

Average particle size(mm) |

6.5 |

0.05 |

4.7 |

0.5-1.7 |

0.5 |

5 |

|

Heavy material accumulation (kg/m3) |

770 |

800 |

1890 |

1100 |

1500 |

750 |

|

Hot air quantity (kg/h) |

3900 |

5400 |

10750 |

9800 |

6500 |

16000 |

|

Inlet gas temperature (oC) |

600 |

165 |

500 |

180 |

650 |

570 |

|

Material outlet temperature (oC) |

|

42 |

100 |

70 |

80 |

75 |

|

Heating method |

coal gas |

Steam electric heating |

heavy oil |

Coal-fired hot blast stove |

heavy oil |

Coal-fired hot blast stove |

|

Loading coefficient |

|

6.3 |

7 |

7.5 |

7.8 |

18 |

|

Speed(rpm) |

4 |

4 |

3.5 |

3 |

4 |

2 |

|

Slope |

0.04 |

0.005 |

0.03 |

0.05 |

0.05 |

0.043 |

|

Number of boards |

12 |

24 |

12 |

22 |

outside the inner cylinder 8 |

6 12 |

|

Dryer diameter(m) |

2.0 |

1.5 |

2 |

2.3 |

The outer cylinder 2 |

The outer cylinder 2.4 |

|

Dryer length(m) |

20 |

12 |

17 |

15 |

10 |

16 |

|

Driving power(kw) |

22 |

7.5 |

15 |

11 |

11 |

15 |

Worshop

User on-site

Delivery