Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

Working principle

The air which is drawn by air blower through the bottom after heating up passes through net board of material hopper. Inside the chamber, the air becomes state of flow under agitating and negative pressure. The moisture is brought away after rapid evaporated. Then target material gets dried in a short time.

Performance characteristics

◎The structure of fluid bed is round to avoid dead corner.

◎There is glitter in the fluidizing bed to avoid agglomerating of raw material and forming canal of flow.

◎The finished material is discharged by turning over the bottom plate. Automatic feeding and unloading system can be designed as required.

◎Sealed negative pressure, air flow through filtration. Easy to operate and easy to clean.

◎The drying rate is quick and the temperature is well proportioned. The drying time of each batch is usually 20-30 minutes, depending on the material.

Adaptive material

◎Using screw to extrude, vibrate granule and to get them dry in a high speed way.

◎It is suitable for drying of granule and powder materials in pharmaceutical, food stuff and chemical industries and so on.

◎Big granule, small block, particle with viscosity.

◎Materials such as konjak, which volume changed during drying.

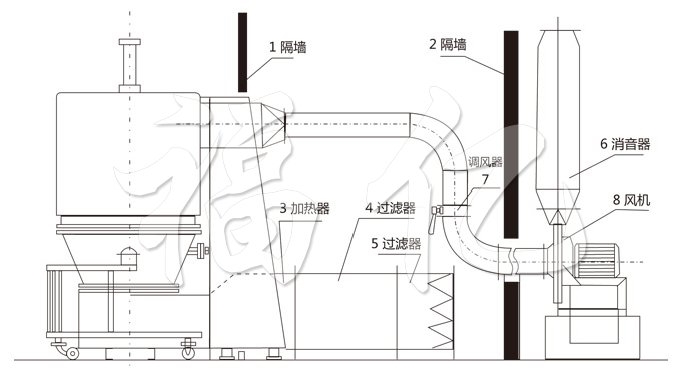

Schematic drawing

1.partition walls 2. partition walls 3.heater 4.Filter 5.Filter 6.Silencer 7.Air regulator 8.Fan

Technical specifications

|

Project |

Model |

||||||

|

Feeding(kg) |

60 |

100 |

120 |

150 |

200 |

300 |

500 |

|

Fan power(kw) |

7.5 |

11 |

15 |

18.5 |

22 |

30 |

45 |

|

Mixing power(kw) |

0.55 |

1.1 |

1.1 |

1.1 |

1.1 |

1.5 |

2.2 |

|

Mixing speed (rpm) |

8~11 |

||||||

|

Steam consumption (kg/h) |

141 |

170 |

170 |

240 |

282 |

366 |

451 |

|

Operating tim (min) |

15-30(According to the properties of material change) |

||||||

|

Host height |

2700 |

2900 |

2900 |

2900 |

2900 |

3300 |

3500 |