Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

Product introduction

According to the requirements of the process, the pressure, the flow rate and the size of the spray hole can be adjusted to obtain the required spherical particles according to a certain size.

Working principle

The working process of the unit is that the feed fluid is ejected by high pressure through the diaphragm pump to eject atomized droplets. The hot air then flows down, and most of the particles are collected at the bottom of the tower. The exhaust gas and its tiny powder are separated by a cyclone separator, and the exhaust gas is exhausted by an exhaust fan. The powder is collected by a pollination cylinder arranged at the lower end of the cyclone separator, and the fan outlet can also be equipped with a two stage dust removing device with a recovery rate of more than 96-98%.

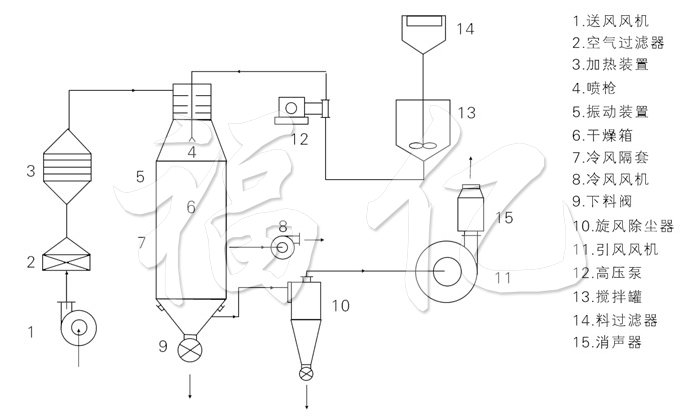

Schematic drawing

1. Fan 2.Air filter 3. Drying device 4. Spray gun 5. Vibrating device 6. Drying device 7. Cold air separation sleeve 8. Cold air fan 9. Blanking valve 10. Cyclone dust collector 11. Fan 12. High pressure pump 13. Mixing tank 14. Material filter 15. Muffler

Performance characteristics

◎The drying rate is fast, and the surface area of the material is greatly increased after atomization. In the hot air, the moisture evaporation can be instantly 95%98%. It takes only ten to ten seconds to finish the dry time, particularly suitable for drying heat sensitive materials.

◎All products are spherical particles, uniform particle size, good fluidity, good solubility, high purity and good quality.

◎Wide range of use, according to the characteristics of materials, you can use hot air drying, you can also use cold air granulation, the adaptability of the material is strong.

◎The operation is simple, stable, easy to control and easy to realize automatic operation.

Adaptive material

Spray dried granule::

◎Chemical: catalyst, resin, synthetic detergent, oil, ammonium sulfate, dyes, dye intermediates, white carbon black, graphite, ammonium phosphate etc..

◎Food: amino acids and analogues, seasonings, proteins, starch, dairy products, coffee extracts, fish meal, meat essence, etc..

◎Pharmaceutical: proprietary Chinese medicine, pesticides, antibiotics, medicinal granules and so on.

◎Ceramics: Magnesium Oxide, China clay, metal oxide, dolomite etc..

◎Spray granulation: all kinds of fertilizer, alumina, ceramic powder, pharmaceutical, steel, chemical fertilizer, heavy metal granular washing powder, Chinese medicine.

◎Spray granulation: amino fatty acid, paraffin, triglycerides, tallow, etc.. Spray crystallization, spray concentration, spray reaction and other aspects are often used.

Technical specifications

|

Model |

Unit |

50 |

100 |

150 |

200 |

300 |

500 |

1000 |

|

Moisture evaporation |

kg |

50 |

100 |

150 |

200 |

300 |

500 |

1000 |

|

Overall dimension (Ф×H) |

mm |

1600×8900 |

2000×11500 |

2400×13500 |

2800×14800 |

3200×15400 |

3800×1880 |

4600×22500 |

|

High pressure pump pressure |

mPa |

2~10 |

||||||

|

Power |

KW |

8.5 |

14 |

22 |

24 |

30 |

82 |

30 |

|

Air inlet temperature |

oC |

140~350 |

||||||

|

Product moisture content |

% |

<5(up to 0.5) |

||||||

|

Material recovery |

% |

>97 |

||||||

|

Electric heating |

KW |

75 |

120 |

150 |

When the temperature is below 200, according to the actual technology |

|||

|

Electric steam |

Mpa+KW |

0.5+54 |

0.6+90 |

0.6+108 |

|

|||

|

Hot blast stove |

Kcal/h |

100000 |

150000 |

200000 |

300000 |

400000 |

500000 |

1200000 |

★The amount of evaporation above is the maximum amount of evaporation.