Changzhou Fuyi Drying Equipment Co., Ltd.

Address: No. 212 Huaxing Road,Jintan Development Zone,Changzhou,Jiangsu,China

Tel: 0086-519-80181222

Fax: 0086-519-80181222

Mobile: 0086-18706143009

Skype:syhjtyz

E-mail: fy@fuyigz.com;

steven@fuyigranulation.com

Contact person: STEVEN

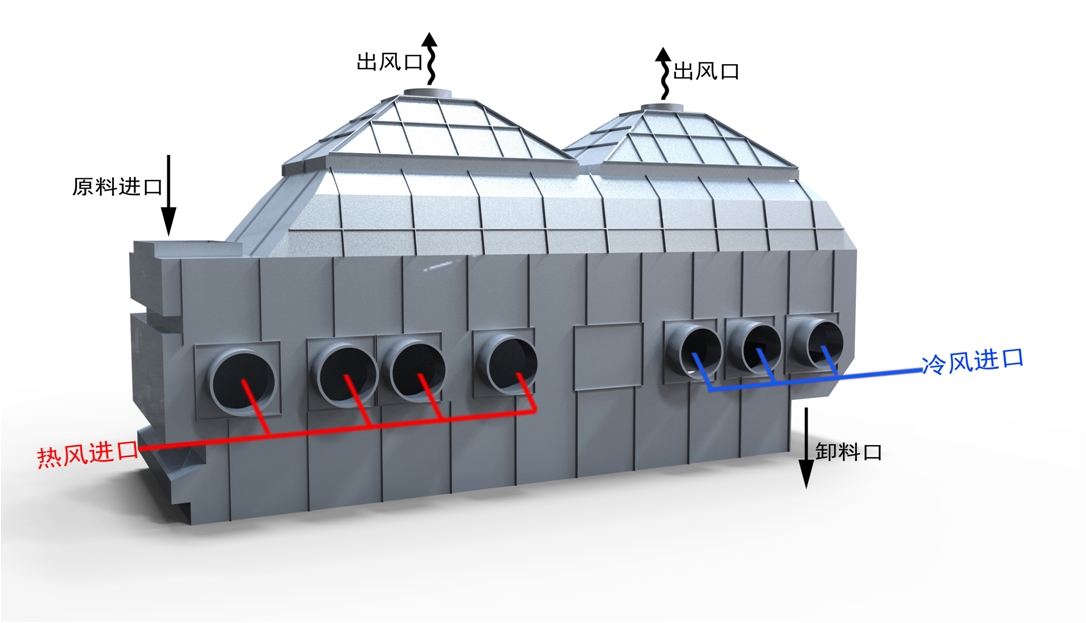

ZLG series vibrating fluidized bed dryer

Introduce:

Fluidized bed dryer is imported from the material into the machine. Under the action of vibrating force, the material is thrown along the horizontal surface of the fluidized bed. The hot air moves upward through the fluidized bed and is heated with the wet material, and the wet air is discharged by the cyclone after the dust is removed by the cyclone separator. The dry material is discharged from the discharging inlet. Apply to chemical, pharmaceutical, food, dehydrated vegetables, food, minerals and other industries of powder, granular materials drying, cooling and other operations.

Working principle:

Material from the feed port into the machine, under the action of vibration material along the horizontal fluidized bed casting, continuous motion, hot air upward through the fluidized bed with wet material after heat exchange, wet air after the cyclone dust discharged from the air outlet drying material from the discharge discharge.

Technical parameter

Model

Fluidized bed area (M)

Inlet temperature (C)

Outlet temperature(C)

Evaporation capacity(kg)

Vibrating motor

Model

Power Kw

ZLG3×0.30

0.9

70-140

40-70

20-35

ZDS31-6

0.8×2

ZLG4.5×0.30

1.35

70-140

40-70

35-50

ZDS31-6

0.8×2

ZLG4.5×0.45

0.025

70-140

40-70

50-70

ZDS32-6

1.1×2

ZLG4.5×0.60

2.7

70-140

40-70

70-90

ZDS32-6

1.1×2

ZLG6×0.45

2.7

70-140

40-70

80-100

ZDS41-6

1.5×2

ZLG6×0.60

3.6

70-140

40-70

100-130

ZDS41-6

1.5×2

ZLG6×0.75

4.5

70-140

40-70

120-140

ZDS42-6

2.2×2

ZLG6×0.9

5.4

70-140

40-70

140-170

ZDS42-6

2.2×2

ZLG7.5×0.60

4.5

70-140

40-70

130-150

ZDS42-6

2.2×2

ZLG7.5×0.75

5.625

70-140

40-70

150-180

ZDS51-6

3.0×2

ZLG7.5×0.9

6.75

70-140

40-70

160-210

ZDS51-6

3.0×2

ZLG7.5×1.2

9

70-140

40-70

200-260

ZDS51-6

3.0×2

Application area

Drying and cooling of powder and granular materials in chemical, pharmaceutical, food, dehydrated vegetable, grain and mineral industries. Such as: citric acid, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, rose L, silk, soybean meal, grains, seeds, slag, sugar etc..

Operation procedure

Process characteristics

1. The vibration source is driven by vibrating motor, which has the advantages of smooth running, convenient maintenance, low noise and long service life.

2. A well proportioned, dry, cooling product can be obtained by a well proportioned, no dead air and blow through phenomenon.

3. Good adjustability, wide range of application. The thickness of the material layer, the moving speed in the machine and the full amplitude change can be adjusted continuously.

4. The material surface damage is small. It can be used for the drying of fragile materials. When the material particles are irregular, it does not affect the work effect.

5. The utility model adopts a totally enclosed structure, effectively prevents cross infection between materials and air, and has a clean working environment.

6.The utility model has the advantages of high mechanical efficiency, high thermal efficiency and good energy saving effect, and can save energy by 30 and 60% compared with the ordinary drying device.